Improving Your Supply Chain: The Benefits of Outsourced Manufacturing

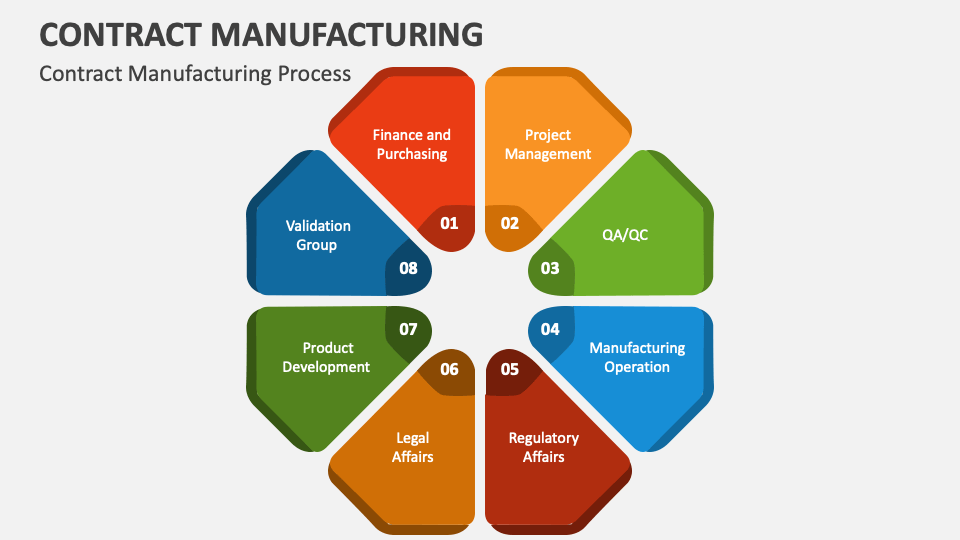

In the current competitive market, businesses are regularly seeking ways to enhance their operations and increase efficiency. A of the best effective approaches that numerous companies are implementing is outsourced manufacturing. Such an approach allows companies to leverage specialized expertise, reduce costs, and simplify production operations while focusing on their core competencies. As industries progress and consumer demands grow, understanding the benefits of contract manufacturing is crucial for businesses looking to improve their logistics chain.

Outsourced manufacturing offers a myriad of benefits that can transform how a company functions. From improved scalability to access to advanced technology, this framework allows companies to adjust quickly in a dynamic environment. By collaborating with experienced manufacturers, companies can improve product quality, optimize lead times, and ultimately drive customer satisfaction. In this article will explore the key benefits of contract manufacturing and how it can function as a driving force for your logistics chain success.

Cost Efficiency and Flexibility

One of the primary advantages of contract manufacturing is the significant cost efficiency it offers businesses. By outsourcing production to specialized manufacturers, organizations can reduce operational costs related to operating their own manufacturing facilities. This approach allows businesses to allocate resources more effectively, focusing on primary activities such as investigation, development, and marketing. Additionally, contract manufacturers often benefit from economies of scale, producing goods at lower costs due to their established processes and technology.

Adaptability is another critical benefit of contract manufacturing. Businesses can quickly scale production up or down in response to consumer needs without the need for significant investments in capital or equipment. This adaptability is particularly advantageous in sectors with variable demand, as it enables companies to adapt to changing market conditions and consumer preferences. By collaborating with contract manufacturers, companies can experiment with new products without the long-term commitment of building their own production lines.

Furthermore, contract manufacturing provides access to sophisticated technologies and expertise that may not be available internally. Partnering with skilled manufacturers allows companies to leverage expert knowledge in production techniques, standards, and logistics. This partnership approach can lead to enhanced product quality and creativity, helping businesses stay agile in a rapidly evolving marketplace. Overall, cost efficiency and flexibility make contract manufacturing an attractive option for companies looking to optimize their supply chain.

Access to Advanced Technology

Contract manufacturing enables businesses to utilize specialized technological know-how that might be unavailable in-house. Many contract manufacturers make significant investments in the newest equipment and software to stay competitive. By partnering with these manufacturers, companies gain access to advanced technologies that can enhance production efficiency and product quality. This can include automated systems, high-precision tools, and innovative production techniques that would be too expensive for individual businesses to forge by themselves.

Furthermore, contract manufacturers often have solid relationships with technology providers, permitting them to stay at the vanguard of industry advancements. This can be particularly advantageous for companies looking to innovate or refine their product lines. By leveraging the latest technologies and state-of-the-art processes, businesses can accelerate their development cycles and introduce products to market at a faster pace. This access to top-tier technology not only enhances output but also strengthens the competitive position of the company in its specific market.

In conclusion, working with a contract manufacturer means that businesses can focus on their core competencies while leaving the technical aspects to specialists. This division of labor allows for a greater focus on research and development, marketing, and customer engagement. As companies rely on their contract partners for technological innovation, they can streamline operations and boost overall business agility, ultimately leading to higher customer satisfaction and enhanced profitability.

Concentrate on Core Strengths

Delegating production through external manufacturing allows companies to concentrate on their strengths. By outsourcing production processes to expert partners, businesses can allocate their efforts on core activities such as creativity, promotion, and client relations. This strategic alignment not only enhances overall efficiency but also drives expansion by allowing organizations to react more swiftly to market demands.

Moreover, utilizing outsourced manufacturing can minimize operational complexity. Companies are freed from the burden of overseeing manufacturing plants, labor, and logistics. This streamlining allows businesses to streamline their operations and dedicate more time to strategic planning and development. As a result, organizations can position themselves more effectively within their industry and enhance their competitive advantage.

Additionally, concentrating on key competencies develops talent and encourages creativity within the organization. Team members can dedicate their talents and expertise to areas that produce the highest returns, leading to increased employee morale and loyalty. This change can spark innovation, as team members are encouraged to explore new concepts and approaches that might have been stifled by the demands of manufacturing. In this way, contract manufacturing serves as a driver for success and change.